What is the Indexing System?

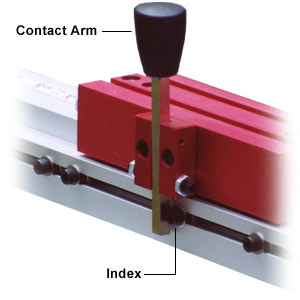

The GlideStop’s Patented Index System allows the stop to return to any preset position quickly and accurately.

The GlideStop’s Patented Index System allows the stop to return to any preset position quickly and accurately.

The Indexes can be easily placed for any standard lengths and can be placed as close as 9/16″ apart.

Unlike other systems our fence is not hindered by multiple stops. The GlideStop can be tightened anywhere along the fence regardless of index placement.

The indexes are meant to be placed in accordance with standard cut lengths. When a standard piece is to be cut, the user needs only to move the stop down to the proper index and tighten to stop. This way everyone in the shop gets the same cut every time.

To preposition the stop, loosen the handle and squeeze the contact arm to bypass the indexes. When the desired index is reached, release the contact arm and slide the stop against the index.

Indexes are easily added and can be positioned in seconds.

To view a video of this system at work, click here.

Interchangeable Package

The Interchangeable Package works on the same principles as the regular GlideStop system. The benefit of having the Interchangeable package is the removable index bar. This system allows you to have multiple index setups and “interchange” them when your job changes. As with the regular GlideStop system, the GlideStop can still be placed anywhere along the fence regardless of index placement.

The Interchangeable Package works on the same principles as the regular GlideStop system. The benefit of having the Interchangeable package is the removable index bar. This system allows you to have multiple index setups and “interchange” them when your job changes. As with the regular GlideStop system, the GlideStop can still be placed anywhere along the fence regardless of index placement.

The interchangeable package gives you the flexibility of having multiple setups for one machine. In seconds you can swap the preprogrammed T-slots and be ready for your next task.

| Interchangeable Packages include: |

| (1) – GlideStop w/ 20 indexes. |

| (1) – 12′ adhesive backed measuring tape. |

| (1) – Std. length of specialized fence. |

| (1) – Specialized T-slot track. |

Specialized lengths include: 4.0′- 6.5′- 8.5′- 10.5′- 12.5′

Additional T-slots sold separately.

This specialized fence system can increase the efficiency of your shop by maximizing the use of your equipment. In seconds you can change your setup and begin production on the next part. This system is best suited for spaced dadoes, spaced boring, mortising and other applications where a number of cut points or holes are needed.

To view a video of this system at work, click here.